—

Market Segment Overview

As a leader in the midstream market for gas processing facilities, Saulsbury has successfully integrated and installed condensate stabilization systems of numerous sizes and configurations, including:

- Single-tower, single product stabilizer systems, producing either an atmospheric condensate product or a Y-grade NGL product

- Two-tower, two product stabilizer systems, producing both an atmospheric condensate product and a Y-grade NGL product

- Three-tower, two product stabilizer systems, producing both a heavy atmospheric condensate product and a Y-grade NGL product

- Stabilizer system design to allow flexibility of either single-product or dual product operation

- Split-flow parallel stabilizer systems with individual or shared overhead compression

- Brownfield installation of stabilizer systems at existing operating facilities

- Stabilizer re-locations and re-installations

—

More Details

Additionally, Saulsbury contains extensive experience in the design and installation of various key balance of plant components necessary to ensure a complete condensate stabilization installation:

- Inlet slug catcher design and installation

- Stabilizer overhead recycle compression design and installation (electric-motor or gas-engine driven units)

- Raw condensate filtration and three-phase separation

- Condensate product storage, truck loading, and vapor handling

- NGL product storage and pumping to pipeline

- Off-spec product handling and recycle for re-processing

—

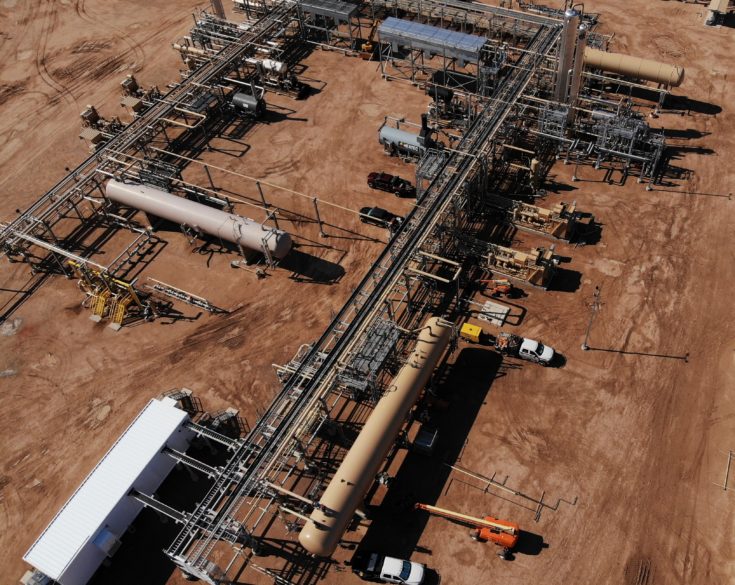

Mentone, Texas

- 15,000-bbl/day Two-Product Stabilizer System

- 8# RVP Condensate and Y-Grade NGL Products

- Two — CAT 3516 Overhead Compressors with Canopy

- NGL Product Surge and Pipeline Pumps

- Condensate Storage and Truck Loading

- All balance of plant equipment and utility storage

—

Coyanosa, Texas

- One – 10,000-bbl/day and one 5,000-bbl/day Two-Product Stabilizer System

- 8# RVP Condensate and Y-Grade NGL Products

- Ability to function in parallel or “either-or” operation

- Two — 600-HP and two 300-HP Overhead Compressors

- NGL Product Surge and Pipeline Pumps

- Condensate Storage (site-erected 10,000-bbl tank) and Truck Loading

- All balance of plant equipment and utility storage

—

Weld County, Colorado

- 10,000-bbl/day Single-Product Stabilizer System

- 8# RVP Condensate Product

- Two — 3,000-HP Overhead Compressors with Building

- Condensate Storage and Truck Loading

- Raw Condensate Unloading System

- All balance of plant equipment and utility storage