—

Industry Overview

With increasing complexity, additional risks, and the fast-track schedules of new projects, many oil and gas companies are electing to use EPC contractors to execute their projects. The Saulsbury EPC model is a fast-track/design-build approach that minimizes costs and maximizes schedules efficiently. This model requires the distinct ability to make timely decisions and react to changes quickly. The EPC functions are all performed in-house, eliminating the need for subcontracting large portions of work. The functions are then integrated to allow for an efficient flow of information throughout the project’s lifecycle, providing greater ability to control the safety, quality, schedule, and cost of the project. All Saulsbury’s project services are performed under the direction of experienced project teams with proven track records of performing with the highest standards of safety and quality.

—

Terminals

Saulsbury’s diverse experience includes the engineering, procurement, and construction of storage terminals for the receipt and transportation of oil and gas.

Our construction, EPC, and E&I professionals’ expertise includes:

- Vapor combustion units

- Dehydration units

- Gathering systems

- Truck, barge, and rail-loading facilities

- Fire suppression

- Construction management

- Oversight of subcontract field-erected tanks

- Custody transfer metering

- Terminal automation equipment

- Motor-operated valves

- Facility power and grounding systems

—

Compression

Gas compression is one of the foundations of Saulsbury’s operational expertise. Over the years, we have installed over one million horsepower and over 250 units of turbine, centrifugal, and reciprocating compression packages. Our extensive compression resume extends throughout the oil and gas value chain from infield booster stations and residue compression at gas processing plants, to mainline compressor stations. Our experience also includes significant CO2 compression for enhanced oil recovery (EOR).

Because of our extensive experience and relationships with equipment packagers, we provide our customers with sophisticated, integrated solutions tailored to individual applications spanning the spectrum of gas inlet streams including varying concentrations of CO2 and H2S.

—

Tank Batteries

Our experts in field service construction specialize in building the facilities required by oil and gas exploration and production companies, including the fabrication, construction, and installation of tank batteries.

Our full-service fabrication shops allow us to create fully engineered, modular designs to meet your current and future needs.

—

Pipelines

Saulsbury’s expertise in fabrication and installation of low and high-pressure piping can develop or maintain a transmission system that will effectively get your assets from source to customer. Our company-owned fabrication facilities are certified ASME U, S, R, and NB standards. Our Piping experts specialize in:

- Gathering systems

- Transportation lines

- Painting and coating

- Pipe design and detailing

- Electrical and instrumentation

- Welded steel, poly, fiberglass, FlexPipe™ Linepipe, Fiberspar™ Linepipe, and Zap-Lok™

Our Field Services Group can support all projects by offering a comprehensive range of services–from installation to maintenance. Our construction teams focus on safety, quality, and excellence resulting in cost-effective project execution.

—

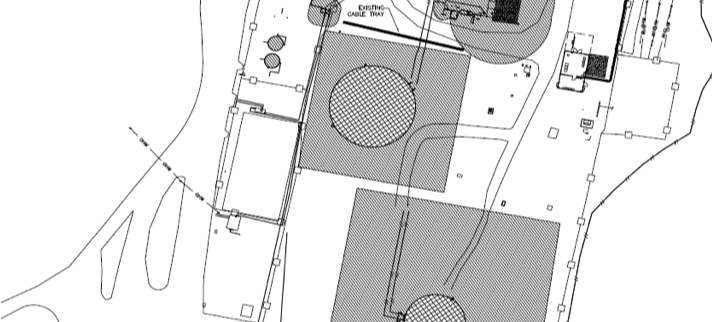

Slug Catchers

Saulsbury possesses extensive experience in the design and installation of harp-style slug catchers of varying sizes and arrangements based on site-specific process conditions, separation requirements, and available plot space. In addition to the complete in-house design, fabrication, and assembly of all inlet, gas outlet, and liquid outlet manifolds, Saulsbury self-performs the turnkey installation of all the slug catcher components and storage tubes/piping from civil work all the way through electrical and instrumentation component installation.

—

Pump Stations

Saulsbury provides end-to-end services for pump station projects including engineering, construction, and maintenance. Our team of professionals extends throughout the U.S. and reflects years of construction experience. We help our clients determine optimal placement, based on a detailed project review, to ensure reliable pressure and efficient delivery every step of the way. Our reputation for safety is without parallel in the industry and our clients have come to depend on the stability that our teams provide.