—

Industry Overview

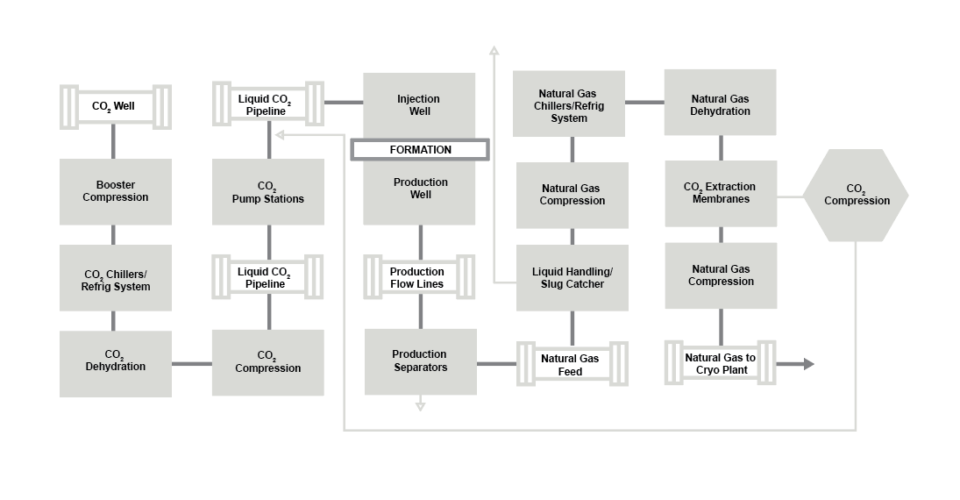

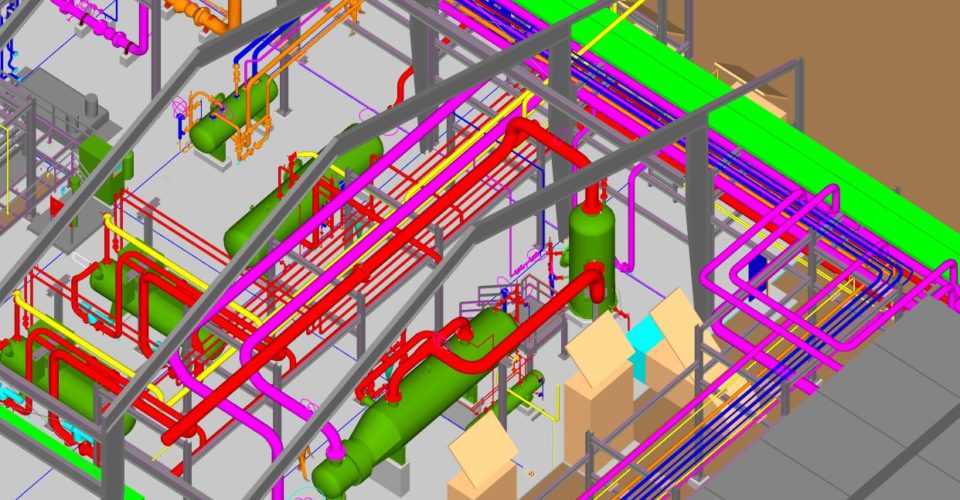

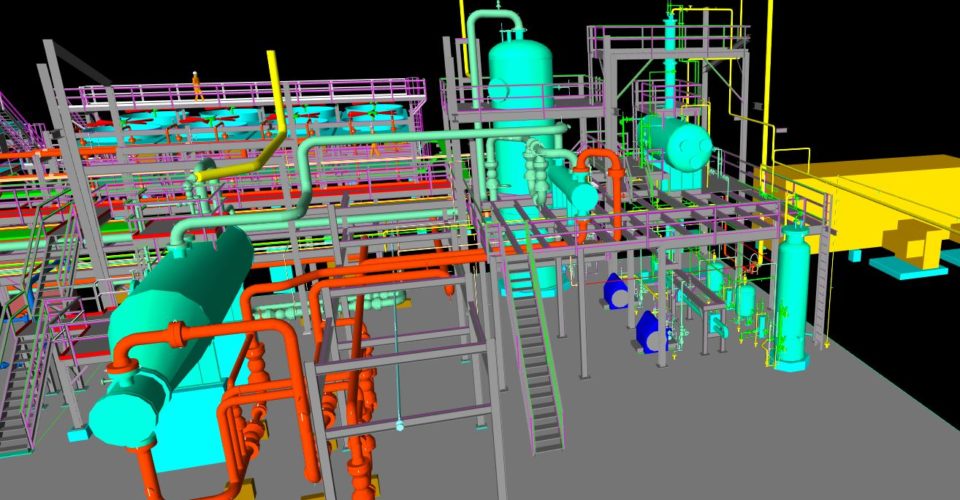

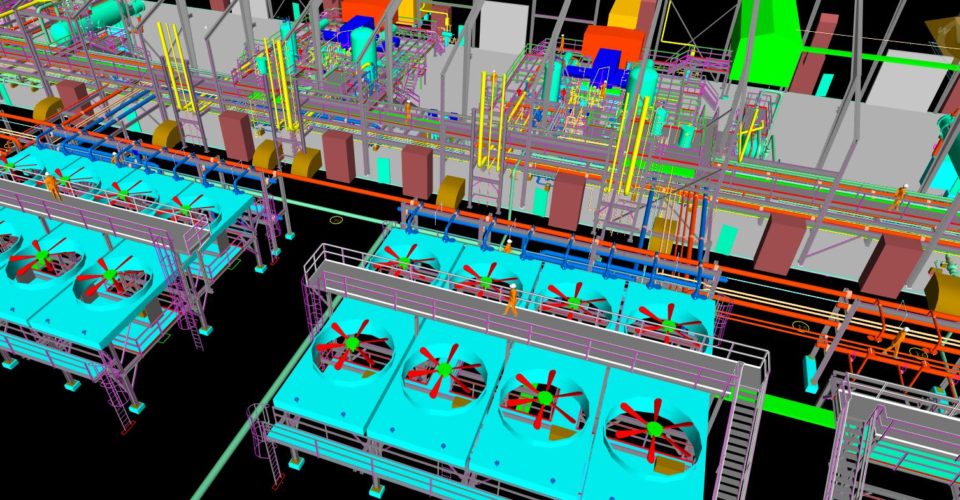

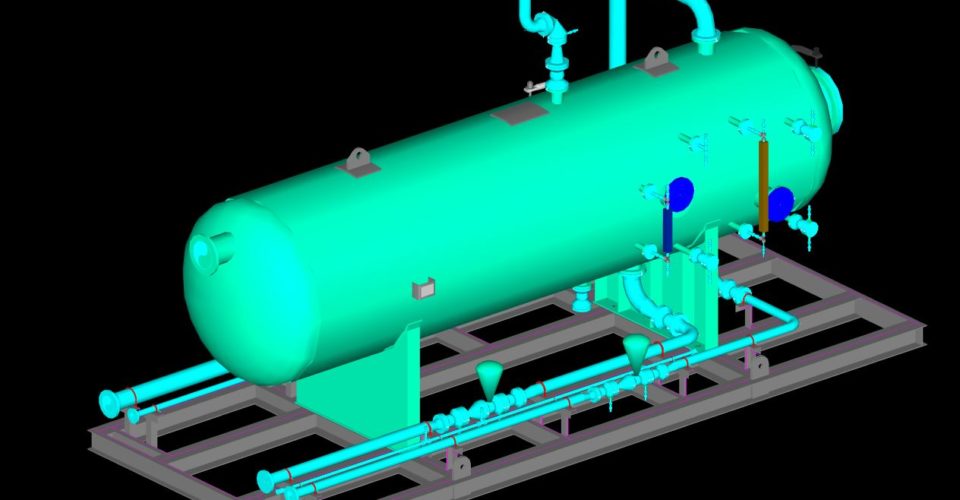

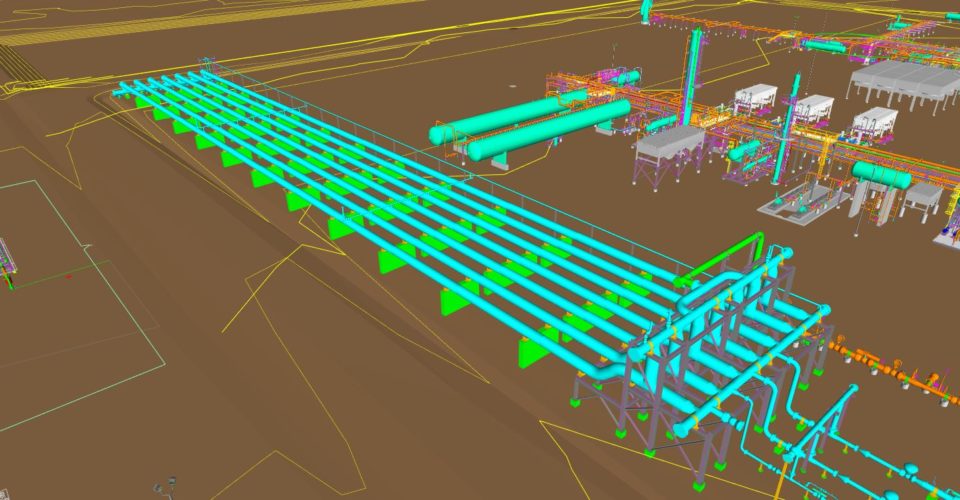

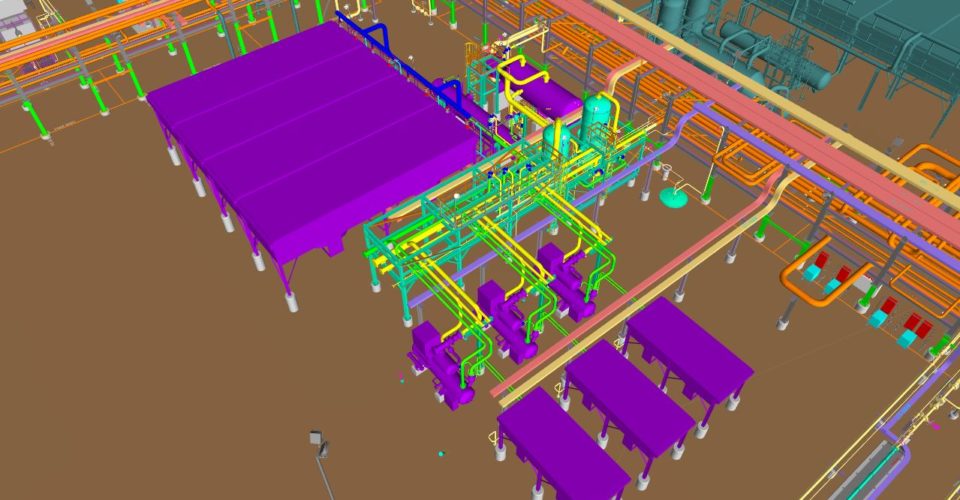

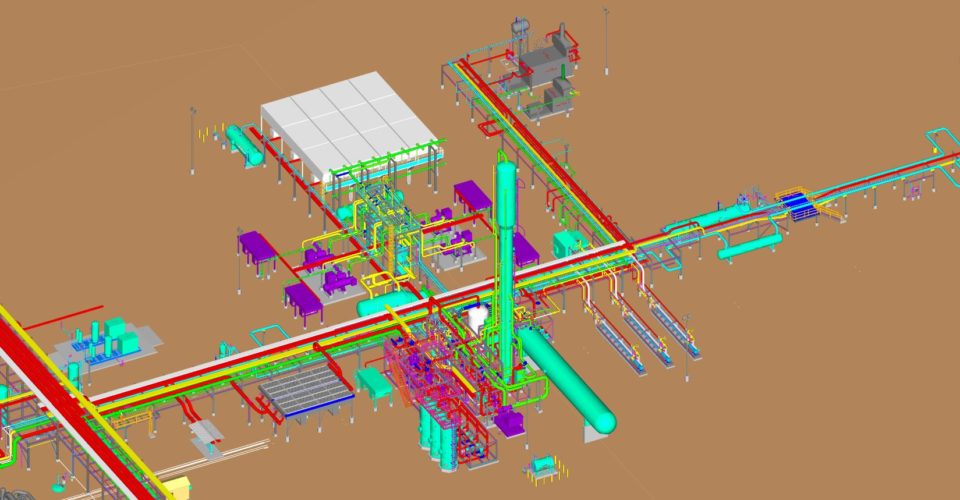

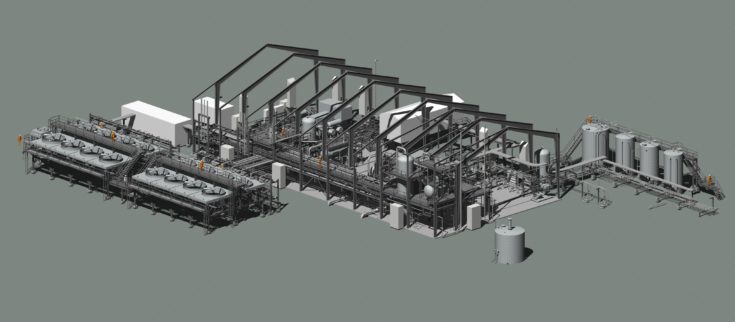

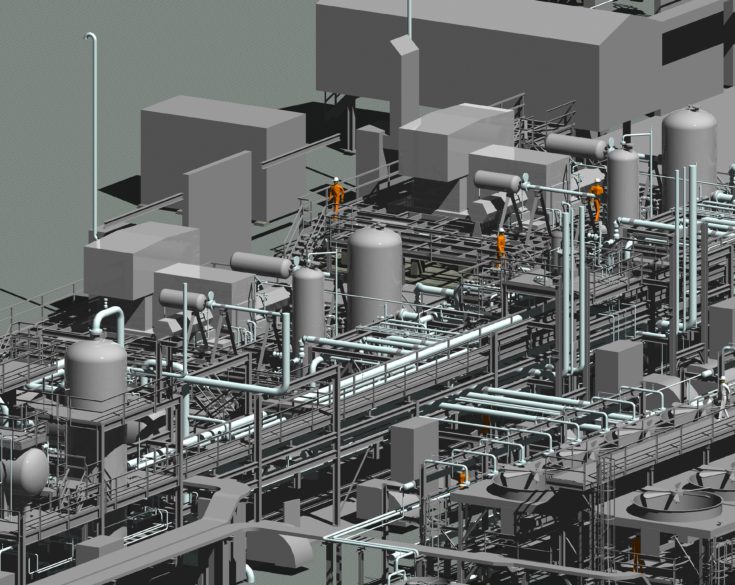

Saulsbury offers industry-leading “cradle-to-grave” support to the design and construction of carbon dioxide (CO2) processing facilities for use in enhanced oil recovery projects. Our project experience covers the entire lifecycle of CO2, from the source field through transportation, injection, and recovery. We are also actively engaged in front-end planning on many CO2 projects. Our CO2 facilities include separating, sweetening, treating, dehydrating, and compressing the CO2 to the required injection pressure.

Saulsbury helps clients address the logistical challenges of readying and retrieving a product from remote locations to major refining and distribution centers. Whether you need maintenance and upgrades or a complete capital project, we will help your operation run efficiently and safely while contributing to a strong ROI.