—

Market Segment Overview

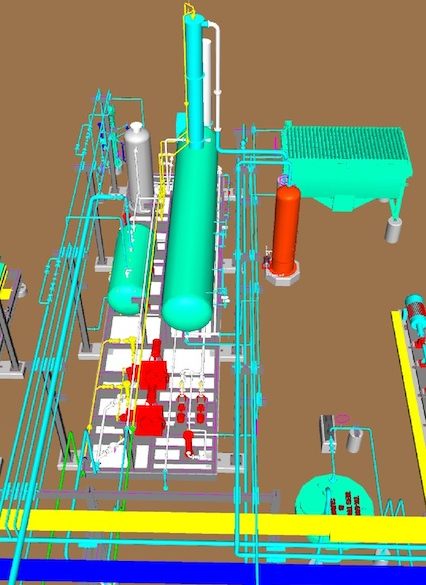

Gas dehydration is a critical operation for the removal of moisture in natural gas in order to prevent excessive free water dropout and hydrate formation in gathering compression and transmission pipelines. This process maintains downstream product specifications for the residue gas and natural gas liquid products that are produced in gas processing plants, and to prevent water freeze-up during regular operation of the gas processing plants.

—

More Details

Saulsbury has successfully integrated and installed gas dehydration and regeneration systems of numerous sizes and configurations, including:

- Triethylene Glycol (TEG) and Diethylene Glycol (DEG) liquid desiccant dehydration and regeneration systems, ranging from 0.25 MMBTU/hr up to 5.0 MMBTU/hr

- Varying reboiler heat sources, including natural gas direct-fired, electric immersion heating elements, and hot oil driven systems

- Split-flow parallel TEG contactors with common regeneration system

- Split-flow parallel TEG contactors with individual, dedicated regeneration systems

- With and without BTEX elimination systems

- Molecular sieve solid desiccant dehydration and regeneration

- Fully-saturated inlet gas water concentration design and installation

- Partial inlet gas water concentration design, with TEG dehydration located upstream for bulk water removal

- Brownfield installation of TEG dehydration and regeneration at existing operating facilities

- Dehydration plant re-locations and re-installation

—

Additionally, Saulsbury contains extensive experience in the design and installation of various mechanisms for handling and disposition of waste gas streams from TEG regenerations systems beyond venting to atmosphere, including:

- Standalone enclosed combustor design and installation

- Vapor recovery unit (VRU) design and installation, for recycle back to the main process streams

- Dedicated feed point/burner on thermal oxidizers that are being utilized for amine regeneration acid gas streams

—

Coyanosa, Texas

- Two — 2.5-MMBTU/hr TEG Dehydration and Regeneration Systems

- Individual Gas Trains, sized at 115 MMSCFD apiece

- Direct-fired heating as Regenerator heat-source

- BTEX Eliminator System with combustor for waste gas incineration

- All balance of plant equipment and utility storage

—

Weld County, Colorado

- 3.0-MMBTU/hr TEG Dehydration and Regeneration System

- 230-MMSCFD Gas Train

- Electric-immersion heating elements as Regenerator heat-source

- BTEX Eliminator System with VRU Compressor for vapor recovery

- All balance of plant equipment and utility storage

—

Mole-Sieve Dehydration

Multiple Locations

- Installation of over 58 mole-sieve dehydration systems upstream of cryogenic plants

- Inclusive of mole-sieve beds, regeneration gas heater, filtration and switching valve skids

- Sizes ranging from 35-MMSCFD to 230-MMSCFD gas flow capacity

- Inlet gas moisture content ranging from 7 lb/MMSCF up to full water saturation