—

Market Segment Overview

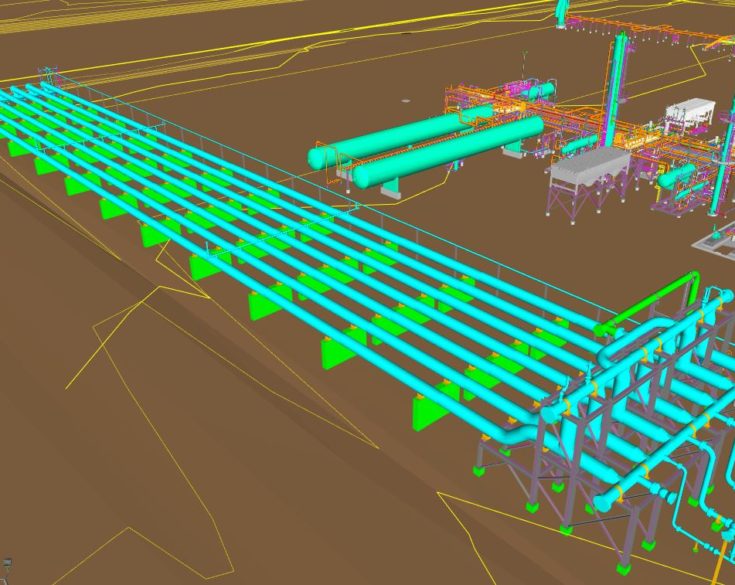

Saulsbury possesses extensive experience in the design and installation of harp-style slug catchers of varying sizes and arrangements based on site-specific process conditions, separation requirements, and available plot space. In addition to the complete in-house design, fabrication, and assembly of all inlet, gas outlet, and liquid outlet manifolds, Saulsbury self-performs the turnkey installation of all the slug catcher components and storage tubes/piping from civil work all the way through electrical and instrumentation component installation.

Saulsbury can readily utilize multiple arrangements and design offerings that can be tailored specifically to the client-specific gas-liquid separation requirements, design conditions, and storage volume requirements. Additionally, Saulsbury contains an in-house design that has been proven and verified through detailed computational fluid dynamic (CFD) studies to achieve <150-micron separation of liquid droplets from the gas outlet stream. Saulsbury utilizes a combination of separation tubes and multiple liquid downcomers to achieve this optimum separation while maximizing the liquid storage capability within a given slug catcher footprint.

—

More Details

Saulsbury self-performs detailed stress analysis coupled with foundation loading and anchoring studies to ensure proper stability and support is achieved for the installation. Saulsbury likewise self-performs all necessary heat trace design, level instrumentation, and bridle specification and design, and all other facets of electrical and instrumentation design requirements to ensure a full turnkey solution can be provided for your slug catcher needs.

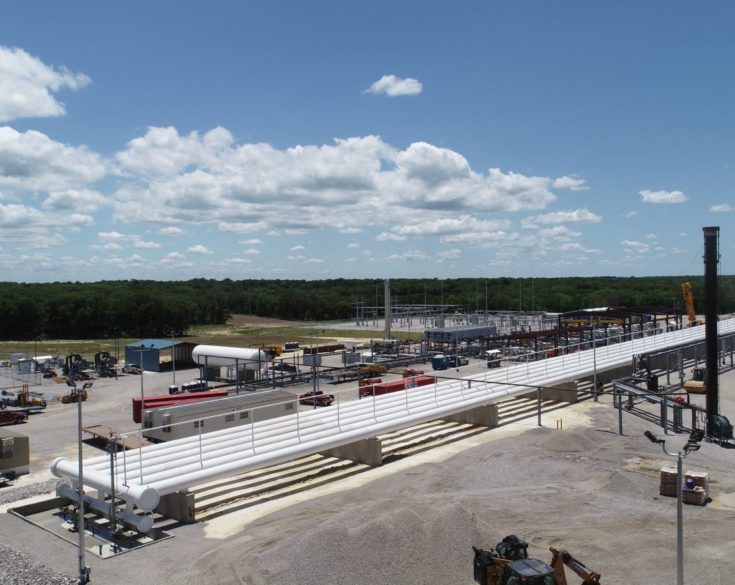

Saulsbury has optimized the construction techniques for harp-style slug catchers. The process maximizes the work that can be performed at grade. The process allows approximately two-thirds of the welding to performed at grade. Saulsbury utilizes rollers, orbital welding and other advanced welding techniques to maximize the welding productivity and quality. Saulsbury reduces or eliminates the need for post-weld heat treat (PWHT) on slug catchers with the engineering design and welding processes utilized specifically for slug catchers. Eliminating PWHT has a significant reduction in cost and schedule to complete the construction. Saulsbury continues to enhance the execution strategy for harp-style slugs to provide the optimal product for our clients.

—

Ardmore, Oklahoma

- 5,400 feet of 36-inch pipe

- Six — 900-feet fingers

- Construction included concrete piers, Initial Slug Catcher for developing a new execution strategy

—

Alva, Oklahoma

- 5000 bbl

- 48″ pipe

- Eight fingers

—

Balmorhea, Texas

- Two — 7,500-bbl slug catchers

- 48-inch pipe, 1.125 thickness

- 9,000 feet of pipe

- 750 feet fingers

—

Jal, New Mexico

- Two — 2,500-bbl slug catchers

- Four — Finger 42” 500Ft Long (2,000 Ft of pipe)

- ¾-inch thick. X70

—

Coyanosa, Texas

- Three — 2,500-bbl slug catchers

- 42-inch pipe

- Four fingers, 300 feet each

—

Woodsboro, Texas

- Three — 1,000 feet fingers

- 36-inch pipe

—

Orla, Texas

- 2,500-bbl slug catcher

- Four — Finger 42-inches 500 feet in length (2,000 feet of pipe)

- ¾”-inch thick X70