—

Project Summary

Saulsbury completed the electrical and civil/structural installation of the equipment for a 17-kilovolt switchyard and a 100-megawatt variable frequency transformer (VFT) at a client’s substation site in Laredo, Texas. Saulsbury supplied all labor, materials construction equipment, tools, consumables, and site facilities.

By installing a VFT at the Laredo Substation, Saulsbury was able to help its client improve the substation’s reliability in the area and decreased the need to operate expensive Laredo area power generation.

The project is noted as only the second VFT installation in the world and the first in the United States.

—

Scope of the Project

- Excavated, formed, poured, and finished all foundations including VFT electrical equipment and control and protection buildings

- Supplied and installed ground connections from equipment and structures to the ground grid

- Installed 17-kilovolt steel structures for bus supports, equipment stands, and switch stands

- Installed and assembled aluminum tubular bus, ACSR cable, jumpers, and associated fittings

- Unloaded and set the steel VFT enclosure, electrical equipment steel building, and steel control and protection building in place

- Assembled and erected the steel control and protection building in place

—

- Unloaded and set all switchyard equipment—transformers and transformer accessories, circuit breakers, switches, static masts and components, 17-kilovolt capacitors and reactors, grounding cabinets, grounding transformers, drive transformers, and station power transformer—in place

- Saulsbury supplied and installed cable trench and all control conduits between yard devices and the cable trench

- Installed 600-volt IAC power cable

- Installed 17-kilovolt switchyard lighting fixtures and wire

- Installed iso phase bus duct from the collector ring and stator of the VFT to the enclosure walls

- Supplied and installed a fire protection system

—

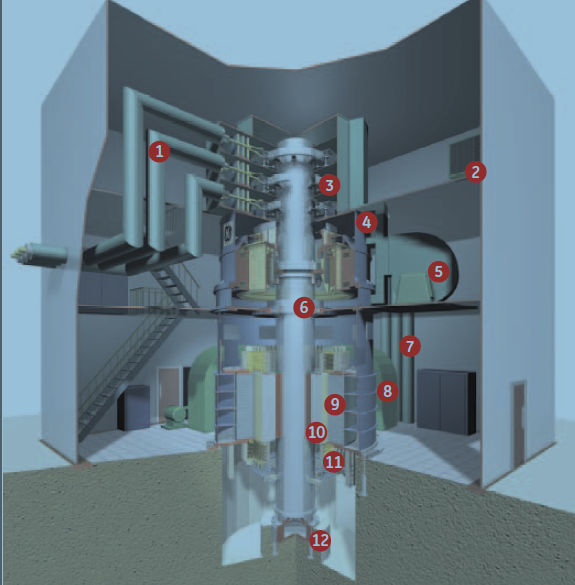

VFT Rotary System

Rotating transformer, DC drive and collector

| 1. Rotor bus duct 2. Air housing 3. Three-phase collector 4. DC torque drive motor 5. DC motor ventilation fan 6. Upper bearing |

7. Stator bus duct 8. Rotating transformer ventilation fan 9. Stator core 10. Rotor core 11. Windings/connections 12. Lower thrust and guide bearing |